Wednesday, November 24, 2010

Zero Energy Home Virginia:Solar PV-show me the money!

Saturday, August 28, 2010

Tightening up to Zero: the Blower Door test Blowout!

Creating a tight envelope is a critical goal in shooting for a zero energy home. And it is not enough to simply apply the correct techniques and materials, it is essential that we have a measure of their effectiveness. This is where the blower door test comes in. A blower door test is a diagnostic tool designed to test the air tightness of buildings.

Creating a tight envelope is a critical goal in shooting for a zero energy home. And it is not enough to simply apply the correct techniques and materials, it is essential that we have a measure of their effectiveness. This is where the blower door test comes in. A blower door test is a diagnostic tool designed to test the air tightness of buildings.

A blower-door fan is sealed into an exterior doorway, all the house vents are temporarily sealed, and the calibrated fan blows air out of the house creating a pressure difference between the inside and outside, which draws air into all of the inadequately sealed cracks, holes and penetrations. A pressure sensing device is used to measure the rate of pressure change/leakage. The data is entered into a standardized formula and the number of Natural Air Changes per Hour (NACH) is derived. Typical production-built homes built under current building codes will score at about 0.5NACH or higher (one complete air change every two hours). A well built, near zero energy home aims for a score of 0.1-0.2NACH. EarthCraft Virginia officials, including Chuk Bowles, Technical Director (tending to the pressure monitor above) and KC McGurren, Executive Director, supervised the testing of our home this week.

As KC is indicating in the picture, the results were encouraging! We registered a score of 0.16NACH, reflecting approximately one complete air change every 6 hours, approximately 3 times tighter than a well built new conventional home! Mark Waring, our builder, said that he was very pleased with this performance, which reflects the tightest home he has built to date. This tightness will minimize the heating/cooling load, reducing the demand on the geothermal system and putting less draw on the solar PV array.

As KC is indicating in the picture, the results were encouraging! We registered a score of 0.16NACH, reflecting approximately one complete air change every 6 hours, approximately 3 times tighter than a well built new conventional home! Mark Waring, our builder, said that he was very pleased with this performance, which reflects the tightest home he has built to date. This tightness will minimize the heating/cooling load, reducing the demand on the geothermal system and putting less draw on the solar PV array. Tuesday, August 3, 2010

Zero in on Geothermal HVAC in Virginia

ratings available. In comparison, Energy Star requirements for geothermal ground source heat pumps are 14.1 EER and 3.3 COP. The two stage compressor and variable speed fan coil contribute to the heightened efficiency while its reliance on R410-A refrigerant protects the ozone layer. The GeoMax2 includes a desuperheater, which uses excess heat to pre-heat your hot water, a nice added benefit. This a split unit, which means that the refrigerant/ compressor unit is seperated from the air handler unit, allowing them to more easily fit in the safety of the conditioned crawl space. The refrigerant/compressor unit is a small gray box about the size of a small bedside table. Once again, great things come in small packages!

ratings available. In comparison, Energy Star requirements for geothermal ground source heat pumps are 14.1 EER and 3.3 COP. The two stage compressor and variable speed fan coil contribute to the heightened efficiency while its reliance on R410-A refrigerant protects the ozone layer. The GeoMax2 includes a desuperheater, which uses excess heat to pre-heat your hot water, a nice added benefit. This a split unit, which means that the refrigerant/ compressor unit is seperated from the air handler unit, allowing them to more easily fit in the safety of the conditioned crawl space. The refrigerant/compressor unit is a small gray box about the size of a small bedside table. Once again, great things come in small packages! But then lets not forget that buried loop I mentioned earlier. This involves 3200 feet of 3/4 inch high density polyethelene pipe buried in two 400 foot runs of trenches dug six feet deep and placed 10 feet apart. Suffice it to say that pretty much snaked over every available inch of our front, back and side yards. It looked like the mole from H_ll attacked our lot.

big bright orange one!

big bright orange one!Friday, July 23, 2010

Insulating our way to Net-Zero: Loose-Fill Cellulose

Saturday, July 10, 2010

Insulating our way to Net-Zero: Icynene

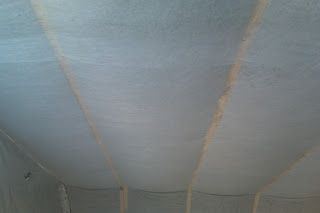

Note in the pictures that all ducting is being kept in conditioned space, increasing energy efficiency.

Sunday, July 4, 2010

Insulating our way to Net-Zero: Wet Spray Cellulose

After completely filling the cavity, a rotating stud scrubber brush is run over the area, leveling it even with the tops of the studs. The cellulose will dry over the next 24 hours, becoming firmer to the touch. No dangerous outgassing is involved, as it does not contain any formaldehyde or respirable microscopic fibers.

After completely filling the cavity, a rotating stud scrubber brush is run over the area, leveling it even with the tops of the studs. The cellulose will dry over the next 24 hours, becoming firmer to the touch. No dangerous outgassing is involved, as it does not contain any formaldehyde or respirable microscopic fibers.  arters.

arters. Saturday, June 19, 2010

Richmond Virginia Zero Energy Home Progress & Appearance

ow far the house has progressed and at the same time illustrate that a ZEH does not have to look unconventional. Placing the Schuco PV panels on the back of the south slanted garage roof aided in this outcome, as they are nearly unnoticeable from the street. I would add that the unusual ceiling planes of the pictured great room have caused Mark, our builder, a lot of thought in terms of where to set the boundary for the conditioned space, how to keep the HVAC ducting in those confines, and where to use loose cellulose versus spray foam insulation. It is becoming increasingly apparent how challenging it is to take the basic principles of a ZEH and translate them into a workable application.

ow far the house has progressed and at the same time illustrate that a ZEH does not have to look unconventional. Placing the Schuco PV panels on the back of the south slanted garage roof aided in this outcome, as they are nearly unnoticeable from the street. I would add that the unusual ceiling planes of the pictured great room have caused Mark, our builder, a lot of thought in terms of where to set the boundary for the conditioned space, how to keep the HVAC ducting in those confines, and where to use loose cellulose versus spray foam insulation. It is becoming increasingly apparent how challenging it is to take the basic principles of a ZEH and translate them into a workable application.Thursday, June 3, 2010

Net Zero Energy Virginia Home and best practices...

RainDrop’s innovative drainage channels keep water out of the wall system. The channels won’t crimp, collapse, or flatten, ensuring water will drain no matter how tightly cladding is nailed to the wall. Because it’s not perforated, RainDrop resists air and water infiltration. Plus it breathes to allow moisture vapor to escape. With its high tear resistance and translucent design, installation is quick and easy with no job site waste. And it stays UV-stable up to 4 months. RainDrop is an ideal secondary weather barrier for fiber cement, vinyl, foam-backed vinyl, and wood sidings and meets the National, Standard, Uniform and International Building Code requirements for air barriers, moisture protection barriers and weather-resistive barriers. It is used on top of the SIS and behind any of the areas to be covered with shingling.

Saturday, May 29, 2010

The window to a zero energy home, Richmond, VA style...

When it came to window choices, there was a lot to consider, because as you increase the tightness and the insulation level of your home, the glazing makes a greater impact on energy usage. And our particular home design has a lot of windows! Looking to the Efficient Windows Collaborative (EWC) for guidance, the 2009 Energy Star standards for Virginia suggested windows with a U-factor (the rate of non-solar heat loss or gain

through a whole window assembly) of .40 and a SHGC (the Solar Heat Gain Coefficient is the fraction of incident solar radiation admitted through a window) of <.40. But our EarthCraft builder reminded us that the EnergyStar standards were going to be tightened starting in 2010, so we set out in search of better windows. The new Virginia Energy Star standards are a U-factor of .32 and a SHGC of <.40, but few suppliers had windows available reflecting the new values yet. After some creat.jpg) ive searching, Mark found us PlyGem MW Pro Series windows with a U-factor of .29 and SHGC of .25 for only $400 more than 2009 rated windows. These are vinyl clad PVC construction, 20 year, double pane, argon gas-filled, low-E glass windows with a Warm Edge technology ( the Warm Edge glass spacer system reduces thermal transfer around the glass perimeter by utilizing a unique U-shaped channel to separate glass panes and interrupt the natural flow of heat to cold). Hopefully the added insulation they provide will reduce the load on our geothermal HVAC system. We are hoping that the lower SHGC will work well, as we have a lot of southeast facing glazing on the back of our house, which because of solar sighting, has little shade in the summer, making excess heat gain in hot muggy Virginia a potential problem. Oh, and that door you see there, that is the Therma-Tru Classic-Craft® Mahogany(waiting to be stained) fiberglass front door, which is also EnergyStar rated. Have to have all the portals covered...

ive searching, Mark found us PlyGem MW Pro Series windows with a U-factor of .29 and SHGC of .25 for only $400 more than 2009 rated windows. These are vinyl clad PVC construction, 20 year, double pane, argon gas-filled, low-E glass windows with a Warm Edge technology ( the Warm Edge glass spacer system reduces thermal transfer around the glass perimeter by utilizing a unique U-shaped channel to separate glass panes and interrupt the natural flow of heat to cold). Hopefully the added insulation they provide will reduce the load on our geothermal HVAC system. We are hoping that the lower SHGC will work well, as we have a lot of southeast facing glazing on the back of our house, which because of solar sighting, has little shade in the summer, making excess heat gain in hot muggy Virginia a potential problem. Oh, and that door you see there, that is the Therma-Tru Classic-Craft® Mahogany(waiting to be stained) fiberglass front door, which is also EnergyStar rated. Have to have all the portals covered...

Monday, May 24, 2010

Solar PV arrives at the Virginia zero energy home!

Every zero energy home needs a renewable power source and ours consists of 20 Schuco SPV 210 panels supplied by Dereck McAvoy of Midsouth Building Supply. These monocrystalline panels are some of the more efficient ones available, rated at PTC/STC 91.5%, indicating that they in effect, under real world conditions, produce very close to their advertised power rating. They are warrantied to produce at least 80% of their initial output for 25 years. They are on the List of Eligible SB1 Guidelines CompliantPhotovoltaic Modules for the Go Solar California program, one of the longest established and most respected state solar programs

Every zero energy home needs a renewable power source and ours consists of 20 Schuco SPV 210 panels supplied by Dereck McAvoy of Midsouth Building Supply. These monocrystalline panels are some of the more efficient ones available, rated at PTC/STC 91.5%, indicating that they in effect, under real world conditions, produce very close to their advertised power rating. They are warrantied to produce at least 80% of their initial output for 25 years. They are on the List of Eligible SB1 Guidelines CompliantPhotovoltaic Modules for the Go Solar California program, one of the longest established and most respected state solar programs . They were installed on the back face of the south facing garage by SunFlower Solar

. They were installed on the back face of the south facing garage by SunFlower Solar  and connected to a SMA Inverter SB 5000us attached to the inside wall of the garage, that wirelessly sends production data to my laptop. The inverter, warrantied for 10 years, converts the DC output to AC and feeds it to the house with the excess going back into the Virginia Power grid with the help of a grid-tie connection to their net metering program. This program allows two way metering, so that excess power can flow into the grid, and needed power (ie. at night) can be drawn out. The arithmetic sum is carried over a 12 month period. If you produce excess power it can be carried forward; if you fall short, it can be subtracted from that sum (or you pay a bill). Any excess that is not used in a 12 month period is donated to the grid, and you get warm fuzzy feelings for your kindness to humanity. All of this now sounds very simple, and the panels look neat and clean. Let me tell you, pulling this together was not simple, neat or clean. It took many hours of active research, several false starts, a motivated, thoughtful builder, and several solar resource experts to make this happen. More on this later.

and connected to a SMA Inverter SB 5000us attached to the inside wall of the garage, that wirelessly sends production data to my laptop. The inverter, warrantied for 10 years, converts the DC output to AC and feeds it to the house with the excess going back into the Virginia Power grid with the help of a grid-tie connection to their net metering program. This program allows two way metering, so that excess power can flow into the grid, and needed power (ie. at night) can be drawn out. The arithmetic sum is carried over a 12 month period. If you produce excess power it can be carried forward; if you fall short, it can be subtracted from that sum (or you pay a bill). Any excess that is not used in a 12 month period is donated to the grid, and you get warm fuzzy feelings for your kindness to humanity. All of this now sounds very simple, and the panels look neat and clean. Let me tell you, pulling this together was not simple, neat or clean. It took many hours of active research, several false starts, a motivated, thoughtful builder, and several solar resource experts to make this happen. More on this later.Wednesday, May 12, 2010

ZEH, SIS, and other energy-friendly acronyms to know

The garage is not insulated, but covered with WEATHERMATE™ Plus – Housewrap to serve as an air and moisture barrier. It is significantly superior in water resistance, air porosity, vapor permeability and tear resistance than the more commonly used Tyvek. It also possesses prolonged UV ray resistance, allowing it to be exposed up to 120 days before significantly degrading (hopefully our garage will not test that limit).

Monday, May 3, 2010

ZEH Virginia, its all in the little things

Building a green ZEH is not one big thing, but a series of many little things. Our builder is using AdvanTech subflooring, a product offered by Huber with a 50 year guarantee that shows significant improvement over both OSB and plywood in stiffness, strength and water resistance, while using no added formaldehyde and meeting the Sustainable Forestry Initiative (SFI) Standard. This produces stiffer, quieter floors while minimizing outgassing. The piece of light blue material you see sticking out from the block in the lower picture is a foam gasket that serves as an air sealing measure along the uneven block and brick. It also is a moisture break to keep water from migrating to the wood from the foundation. The aim of maintaining an extremely tight "envelope" with respect air and moisture infiltration is a guiding principle that directs innumerable building product choices and practices when constructing a zero energy home. Mark, our builder, is shooting for the lowest HERS rating house in Virginia, so each of these decisions is made with efficiency and best practice in mind.

Building a green ZEH is not one big thing, but a series of many little things. Our builder is using AdvanTech subflooring, a product offered by Huber with a 50 year guarantee that shows significant improvement over both OSB and plywood in stiffness, strength and water resistance, while using no added formaldehyde and meeting the Sustainable Forestry Initiative (SFI) Standard. This produces stiffer, quieter floors while minimizing outgassing. The piece of light blue material you see sticking out from the block in the lower picture is a foam gasket that serves as an air sealing measure along the uneven block and brick. It also is a moisture break to keep water from migrating to the wood from the foundation. The aim of maintaining an extremely tight "envelope" with respect air and moisture infiltration is a guiding principle that directs innumerable building product choices and practices when constructing a zero energy home. Mark, our builder, is shooting for the lowest HERS rating house in Virginia, so each of these decisions is made with efficiency and best practice in mind.

Saturday, May 1, 2010

ZEH design blueprint

Sunday, April 25, 2010

Starting the envelope

The foundation walls are up and the workers are laying the 2" Dow Styrofoam Scoreboard insulation against the walls. This forms the continuous insulation (R-10) and moisture barrier along the masonry wall that is vital to our conditioned crawl space. It takes the place of any insulation that would normally be against the floor. The joints between pieces are sealed with expanding spray foam sealant, creating the continuous barrier. There will be a vinyl strip below the installed insulation that we will seal the floor vapor barrier to, once the house is dried in. It is already clear in watching the workers, that while thoughtful design and product choice are important in reaching the desired energy goals, correct application and attention to detail is equally important. It is noted that Dow STYROFOAM products are CFC Free, they do not contain fully halogenated chlorofluorocarbons (CFCs) regulated by the United Nations Environment Program (UNEP) in the Montreal Protocol.

The foundation walls are up and the workers are laying the 2" Dow Styrofoam Scoreboard insulation against the walls. This forms the continuous insulation (R-10) and moisture barrier along the masonry wall that is vital to our conditioned crawl space. It takes the place of any insulation that would normally be against the floor. The joints between pieces are sealed with expanding spray foam sealant, creating the continuous barrier. There will be a vinyl strip below the installed insulation that we will seal the floor vapor barrier to, once the house is dried in. It is already clear in watching the workers, that while thoughtful design and product choice are important in reaching the desired energy goals, correct application and attention to detail is equally important. It is noted that Dow STYROFOAM products are CFC Free, they do not contain fully halogenated chlorofluorocarbons (CFCs) regulated by the United Nations Environment Program (UNEP) in the Montreal Protocol.

Saturday, April 17, 2010

An enlightening experience...

Wednesday, April 7, 2010

A Greener Foundation

busy pouring our foundation. In talking with our EarthCraft builder, we learned that he is using fly ash concrete, a form of concrete which replaces some of the cement in the mixture with fly ash, the fine powdery residue from coal combustion. This produces a concrete that is stronger, more durable and easier to work with and diverts that fly ash generated by our coal-fired power plants from ending up in our landfills. Fly ash containing concrete mixes can receive LEED credit under the guidelines established by US Green Building Council. In the vein of there being nothing new under the sun, a form of volcanic fly ash concrete was used by the Romans in building the Coliseum and the first domestic use of fly ash concrete was in 1929 in the construction of the Hoover Dam.

busy pouring our foundation. In talking with our EarthCraft builder, we learned that he is using fly ash concrete, a form of concrete which replaces some of the cement in the mixture with fly ash, the fine powdery residue from coal combustion. This produces a concrete that is stronger, more durable and easier to work with and diverts that fly ash generated by our coal-fired power plants from ending up in our landfills. Fly ash containing concrete mixes can receive LEED credit under the guidelines established by US Green Building Council. In the vein of there being nothing new under the sun, a form of volcanic fly ash concrete was used by the Romans in building the Coliseum and the first domestic use of fly ash concrete was in 1929 in the construction of the Hoover Dam.Wednesday, March 31, 2010

Wow.. it's going to really happen!!

that might have otherwise been spared. That left us with a rather bleak picture, and took most of our privacy away. We took heart in the knowledge that Mark, our builder, had recycled all of the cut wood to the lumber mill, for mulch, pulpwood and lumber. I believe that is part of the EarthCraft building guidelines. In looking at the back of the cleared lot, and thinking of how to gain some privacy without creating problem shading, I realized that in the future there may be a place for solar-sensitive landscape design (ie. now what can I plant back there that will provide cover and not grow more than about 15 feet high?).

that might have otherwise been spared. That left us with a rather bleak picture, and took most of our privacy away. We took heart in the knowledge that Mark, our builder, had recycled all of the cut wood to the lumber mill, for mulch, pulpwood and lumber. I believe that is part of the EarthCraft building guidelines. In looking at the back of the cleared lot, and thinking of how to gain some privacy without creating problem shading, I realized that in the future there may be a place for solar-sensitive landscape design (ie. now what can I plant back there that will provide cover and not grow more than about 15 feet high?).Saturday, March 27, 2010

ZEH: it's a system

...it is basically designed as a single story home, with some bonus rooms upstairs...it will be all brick with a semi-detached garage (the why of that comes later)...the walls will be R16 and the attic R38...the walls will use wet spray cellulose and the attic loose cellulose...a conditioned crawl space...we are also using a new product on the outside of the stud walls, Dow Styrofoam SIS, (structural insulated sheathing) which will be taped, forming an air/vapor barrier, an extra layer of insulation, a shield against thermal bridging of the studs, and a structural element...pretty cool...with respect to the R levels, they are more than sufficient for our climate, as the wet spray cellulose significantly increases the thermal mass of the house... along with the tightness of the house (we aim for less than a .20 Natural Air Exchanges per Hour blower door result and a less than 4% of floor area served leakage to outside duct test result; an ERV will be installed for ventilation), the increased thermal mass may even eliminate the need for a setback thermostat, as the temperature of the house should remain incredibly stable...we are going to look into cool roofs/radiant heat barriers, but setting up the heating/coolng "firewall" at the attic floor may be more cost effective....

...we are looking at double pane, vinyl clad, low E, argon windows, with U value of .33 and SHGC of.30...we are looking into a new model with a U below .30, getting a price difference on that...

...Caroma (the reviews say they never clog) 1.28/0.8 dual flush toilets to save water...

...the HVAC system is proposed to be a Comfortaire GeoMax2 geothermal heat pump of 4 ton capacity with desuperheater rated @ 23.7/16.6 EER & 4.0 COP...hot water will be pre-heated by the desuperheater and then go to a 98% efficient Navien tankless condensing water heater with a built in recirculation pump & mini buffer tank for a digital timer controlled recirculation loop to prevent the dreaded "cold water sandwich" you can get with tankless water heaters...the solar grid-connected PVC array will consist of 20 Schuco Monocrystalline 210 panels (4.2kW) and a SunnyBoy inverter mounted on a true south oriented garage roof...

We will begin to look at each of these features as the build progresses, analyzing their benefits and potential assets and seeing how they may complement (and hopefully not compromise) the "system". Stay tuned.